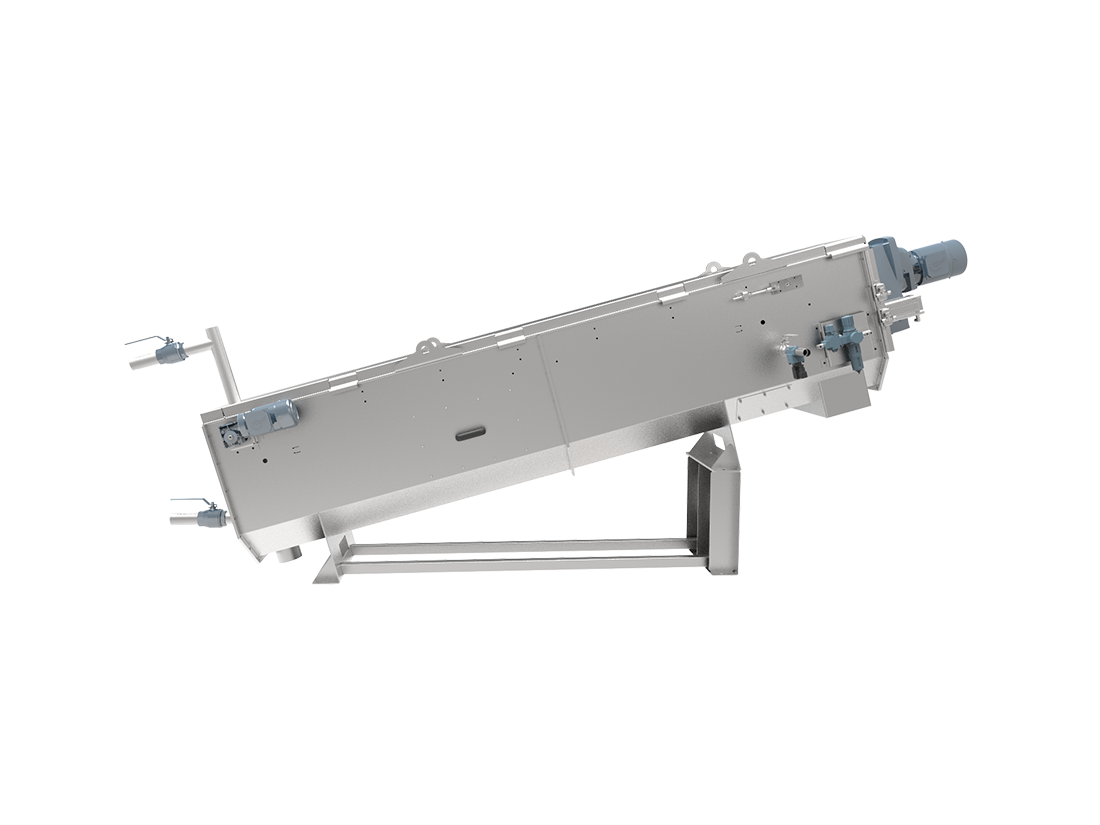

WASTEWATER SCREEN PRESS FL/SD SDF SERIES

The wastewater screen press comprises a screening zone, transport zone and compaction zone. The stationary screen basket captures the suspended solids and is cleaned by rotating brushes and a spray water system. The captured solids are then transported to the compaction zone by means of an inclined screw where they are compacted and dewatered. The degree of compaction and dewatering depends on the type of solids being processed.

Features:

- Separation of suspended solids from liquid flows

- For installation above ground

- Fixed screen drum captures suspended solids

- Rotating brushes remove solids from screen surface

- Inclined screw transports solids to compaction zone

- Solids discharge vertically into receiver bin or conveyor

- Compaction of solids before discharge

- Automatic washing in the screen zone

Technical specifications:

| Material | 304ss, 316ss |

| Screw | 304ss, 316ss, micro alloy steel |

| Wear bars | 304ss, 316ss |

| Aperture | 0.25 – 6mm wedge wire/perforated holes |

| Screen width | 200 – 900mm |

| Flow rate | 8 – 490 m3/h clean water |

| Solids dryness | up to 45% |

| Cleaning | rotating brushes and spray nozzles in screen zone |